Risk calculation for the protection of your machines and equipment

Risk assessment

A requirement for the CE mark

The manufacturer or their authorized representative confirms by means of the CE marking according to the European Regulation (number 765/2008) “that they accept responsibility for the conformity of the product with all the requirements for affixing it contained in the relevant community harmonization legislation”.

The basis for the CE mark is the risk assessment, the aim of which is to operate and design machines in such a way that neither when used in accordance with their intended purpose nor in the event of foreseeable operating errors will they cause damage to health and accidents.

It has been determined that hazards present on a machine will eventually lead to personal injury if no appropriate protective measures have been taken beforehand. The protective measures, which are carried out by the manufacturer on the basis of the risk assessment, effectively reduce the residual risk of existing dangers on the machine. Ideally, such measures are already taken during the design phase, as they are then usually easier to implement than at a later stage by the user or manufacturer. In addition, it saves money and time during production and design, and helps to identify machine risks as soon as possible. In this way, cost-intensive reworking can be avoided.

It is important to us to carry out the risk assessment together with you, to document it in a legally compliant manner and to support you in carrying out the entire conformity assessment procedure for your products. This includes hand tools, products of classical mechanical engineering, complex conveyor systems or machine tools.

In the field of special machine construction, we can look back on many years of experience in conformity assessment:

- Laser systems

- Test stands

- Robot systems

- Own productions

- remote-controlled and autonomously driving vehicles

- Interfaces between different machine parts

- special machine tools

- interlinked production machines, for example for the automotive industry

Documents we create for you comply with the guidelines and standards. Please contact us to arrange a consultation appointment.

Directive 2006/42/EC (Machinery Directive)

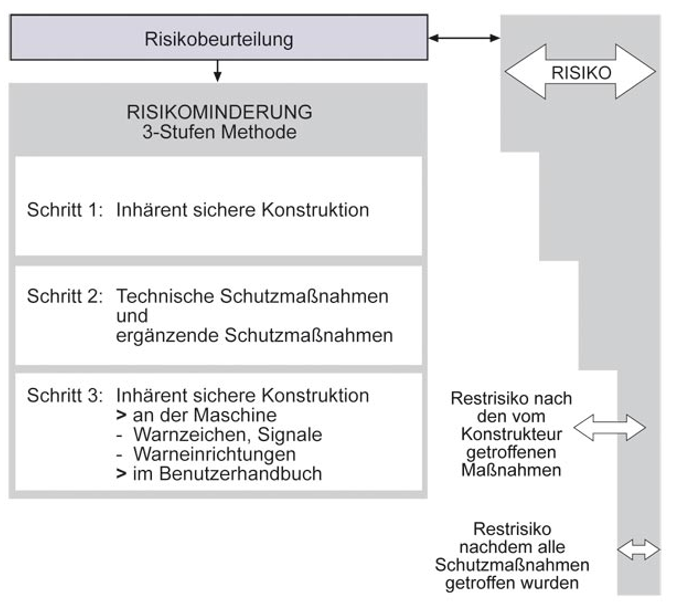

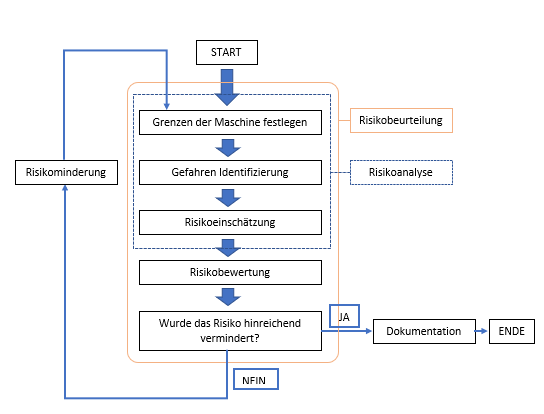

Directive 2006/42/EC (Machinery Directive) stipulates that the hazards and any risks posed by the machine must be identified in a risk assessment, the risk reduction measures must be determined in accordance with the 3-stage method and the machine must be constructed on the basis of the results.

Annex 1 of the Machinery Directive 2006/42/EC states

“The manufacturer of a machine … must ensure that a risk assessment is carried out to determine the health and safety requirements applicable to the machine. The machine must then be designed and constructed taking into account the results of the risk assessment”.

We create the entire risk assessment for your machine by ourselves.

On the basis of the risk assessment, we determine the dangers and risks arising from a machine.

Iterative process risk assessment

3-step process for risk reduction